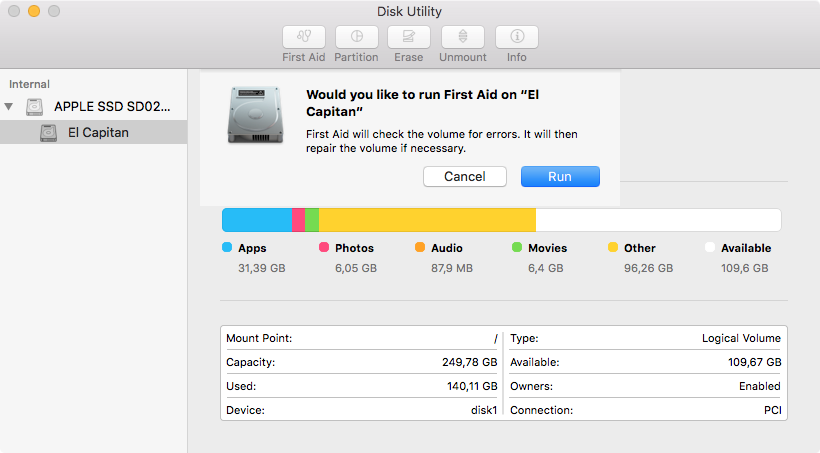

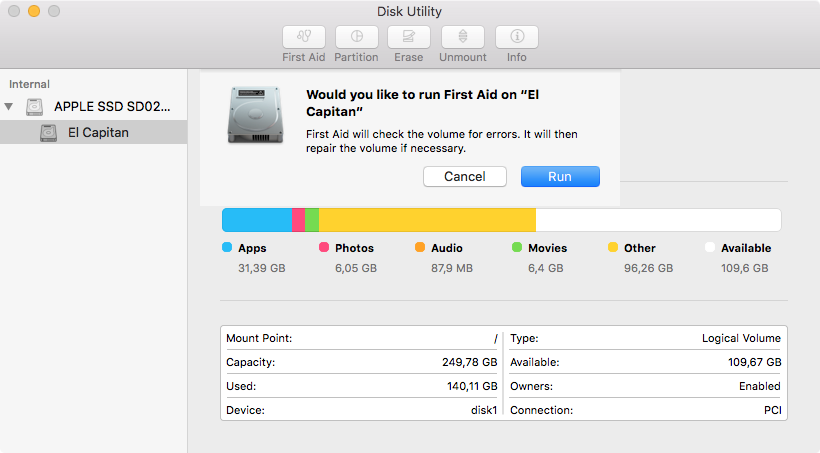

Hold the angle grinder with both hands ensuring the side handle is inserted on the side of the unit that gives the best grip for the work activity. punch and hammer) can damage the disc and grinder. Use the tightening tool supplied by the grinder manufacturer to tighten the disc.  Fit the right sized disc that has a hole matching the spindle flange. Use the angle grinder with the correct guard supplied by the manufacturer. Unsafe excessive clearance for the central hole on 356 mm disc on 9 inch spindle flange.Ģ30 mm (9 inch) angle grinder with guard and right sized disc fitted. Unsafe 230 mm (9 inch) angle grinder with 356 mm (14 inch) disc fitted and guard removed If the disc hole is too big for the spindle flange, the disc may be off centre, become unbalanced, vibrate excessively and rapidly lead to it shattering. For example, the hole size of a 14 inch (356 mm) cut-off wheel is typically 25.4 mm compared to 22.3 mm on a 9 inch (230 mm) cutting disc (see Photograph 2). As the disc diameter increases so will the hole size. there is also a greater risk of the blade being damaged when the angle grinder is put down and the weight of the grinder is resting directly on the disc.Īnother factor that increases the risk of disc failure is when the central disc hole size is too large for the spindle flange on the angle grinder. the user's hand will be closer to the unguarded moving blade. there is nothing to stop the broken pieces hitting the user. Guards should be provided and used on all power tools where there is a risk of the disc ejecting, disintegrating or cutting the worker. Discs are not designed for the higher speed, and if used, risk the possibility of the disc shattering and striking the user and others.

Fit the right sized disc that has a hole matching the spindle flange. Use the angle grinder with the correct guard supplied by the manufacturer. Unsafe excessive clearance for the central hole on 356 mm disc on 9 inch spindle flange.Ģ30 mm (9 inch) angle grinder with guard and right sized disc fitted. Unsafe 230 mm (9 inch) angle grinder with 356 mm (14 inch) disc fitted and guard removed If the disc hole is too big for the spindle flange, the disc may be off centre, become unbalanced, vibrate excessively and rapidly lead to it shattering. For example, the hole size of a 14 inch (356 mm) cut-off wheel is typically 25.4 mm compared to 22.3 mm on a 9 inch (230 mm) cutting disc (see Photograph 2). As the disc diameter increases so will the hole size. there is also a greater risk of the blade being damaged when the angle grinder is put down and the weight of the grinder is resting directly on the disc.Īnother factor that increases the risk of disc failure is when the central disc hole size is too large for the spindle flange on the angle grinder. the user's hand will be closer to the unguarded moving blade. there is nothing to stop the broken pieces hitting the user. Guards should be provided and used on all power tools where there is a risk of the disc ejecting, disintegrating or cutting the worker. Discs are not designed for the higher speed, and if used, risk the possibility of the disc shattering and striking the user and others.

Photograph 1 shows an angle grinder with the wrong size cutting disc fitted and the guard removed. Larger angle grinders are manufactured with lower revolutions per minute (RPM) speeds than smaller angle grinders, so that the edge speed of the disc always remains around 70 m/s.įitting a 14 inch (356 mm) cut-off disc to a 9 inch (230 mm) angle grinder will increase the edge speed excessively to at least 120 m/s (430 kmph). peripheral speed) of approximately 70 metres/second (250 kmph). In some cases the guards have been removed and the grinder fitted with a 14 inch (356 mm) cut-off disc.Ĭutting discs are usually designed for a maximum outside edge speed (i.e. One major contributing factor is the use of cutting discs that are too large for the angle grinder. In another incident the disc jammed and the angle grinder kicked back and cut the worker's wrist. It appears that due to the high impact of the projectile it caused fatal internal injuries.

The worker was killed when part of a broken disc struck the worker's chest. In early February 2016, a Queensland worker received fatal injuries while operating a 230 mm (9 inch) angle grinder. The purpose of this safety alert is to highlight the risks associated with removing guards and using incorrect discs on angle grinders.

0 kommentar(er)

0 kommentar(er)